Background

Bluetooth: Bluetooth (BT) is a radio communication standard first proposed in 1996 by Intel, Ericsson, and Nokia to support short-range wireless connectivity and facilitate collaboration between different products and industries. The standard has evolved as technology improved and today, Bluetooth support is included in all popular mobile phones and most personal computers (PCs).

BlueRail Trains: My first contact from BlueRail Trains was January 2016 when they were working on FCC certification of their first Bluetooth product. I've been watching their progress for 7 years. Their collaboration with SoundTraxx and release of the Blunami product is a significant accomplishment.

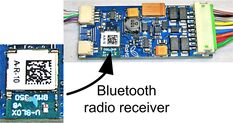

U-Blox: U-Blox is a global provider of positioning and wireless communication technologies that

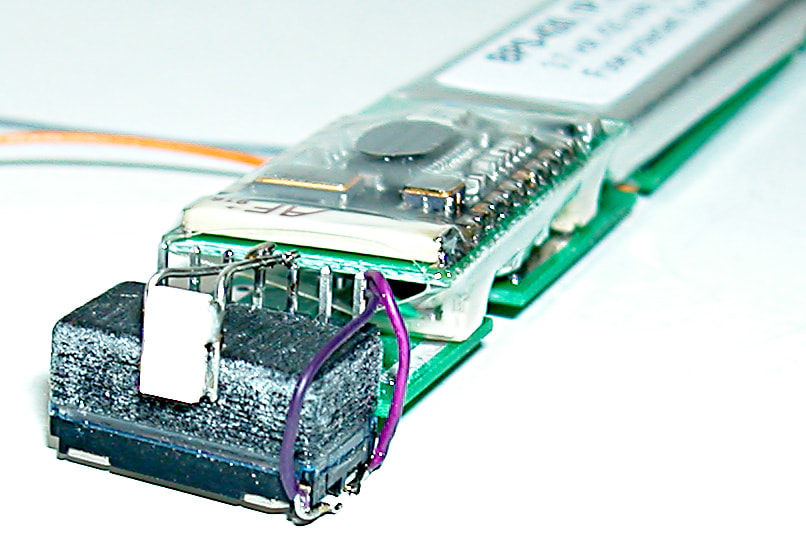

acquired Rigado’s Bluetooth modules business in July 2019. Since BlueRail's early development used Rigado's Bluetooth radio module, their firmware obviously carried over to the U-Blox chip that we find in Blunami.

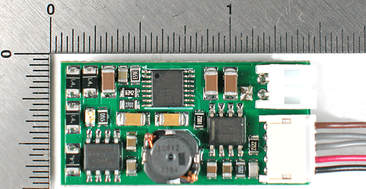

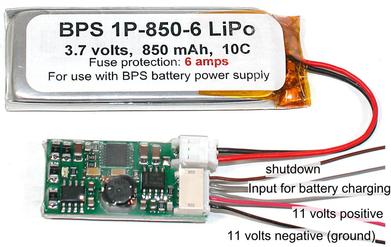

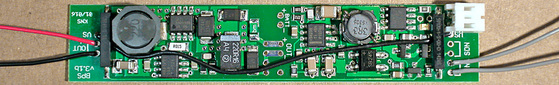

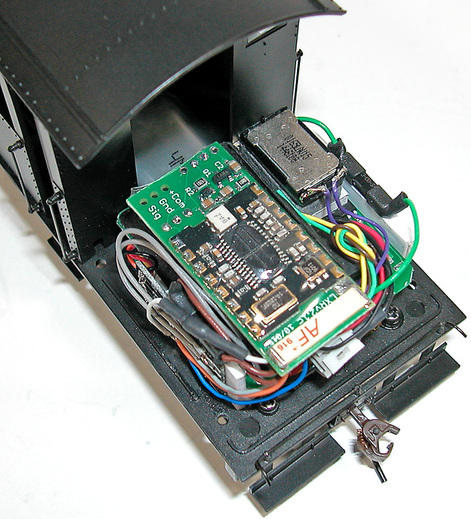

SoundTraxx: Sophisticated radio communication has been added to the TSU-2200 decoder while retaining the option of standard DCC control. The magic is embedded in firmware within the U-Blox radio module.

Blunami

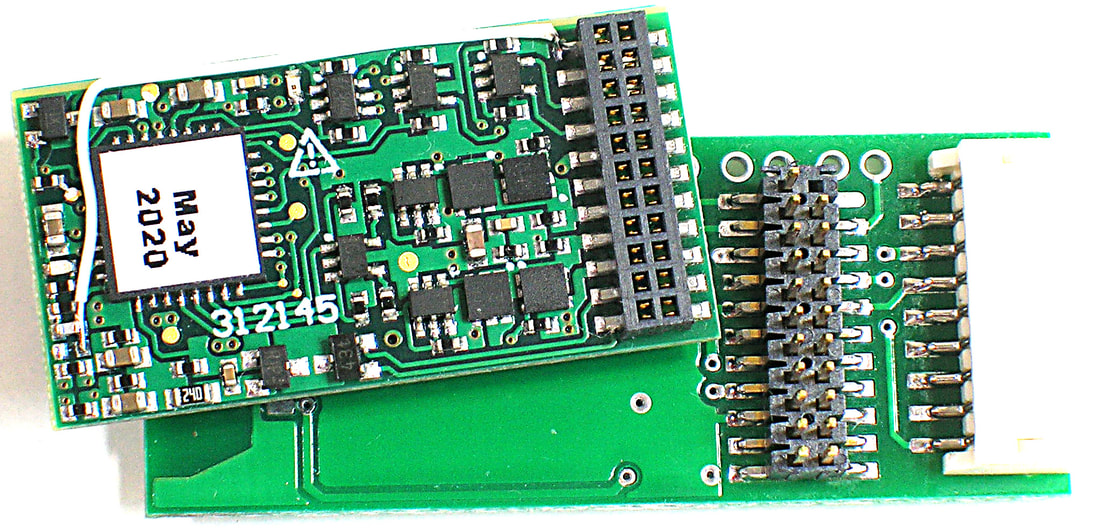

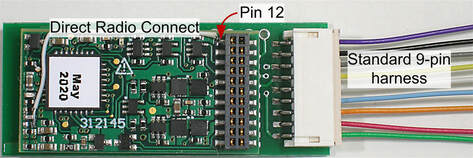

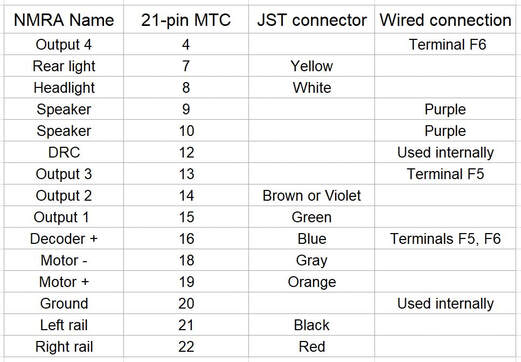

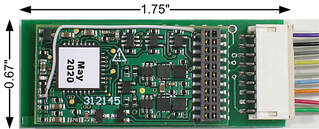

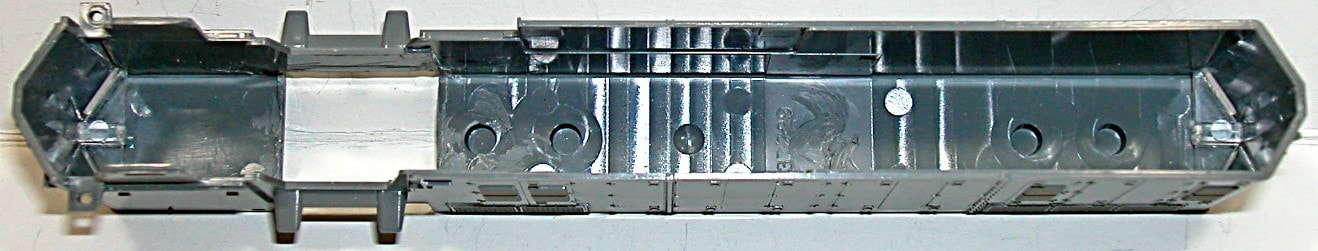

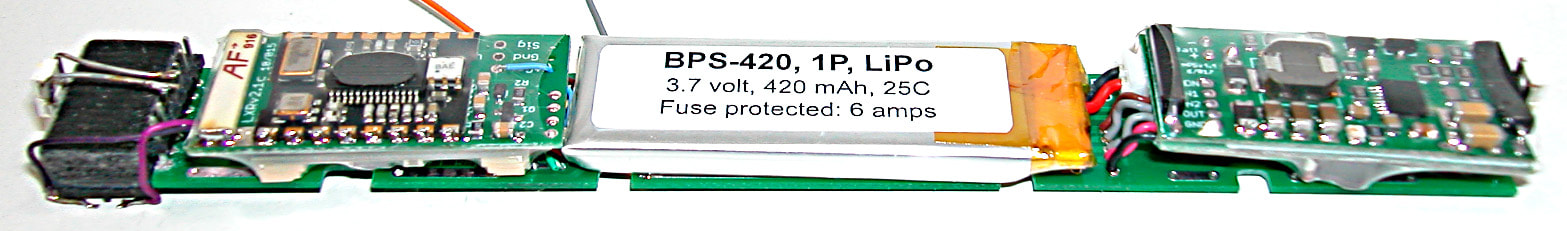

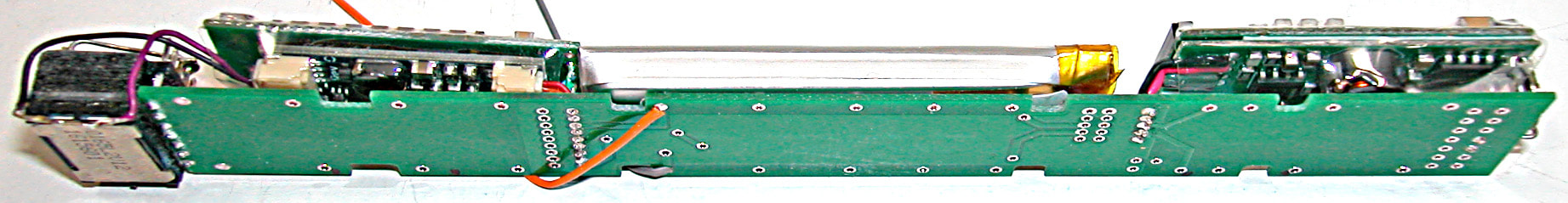

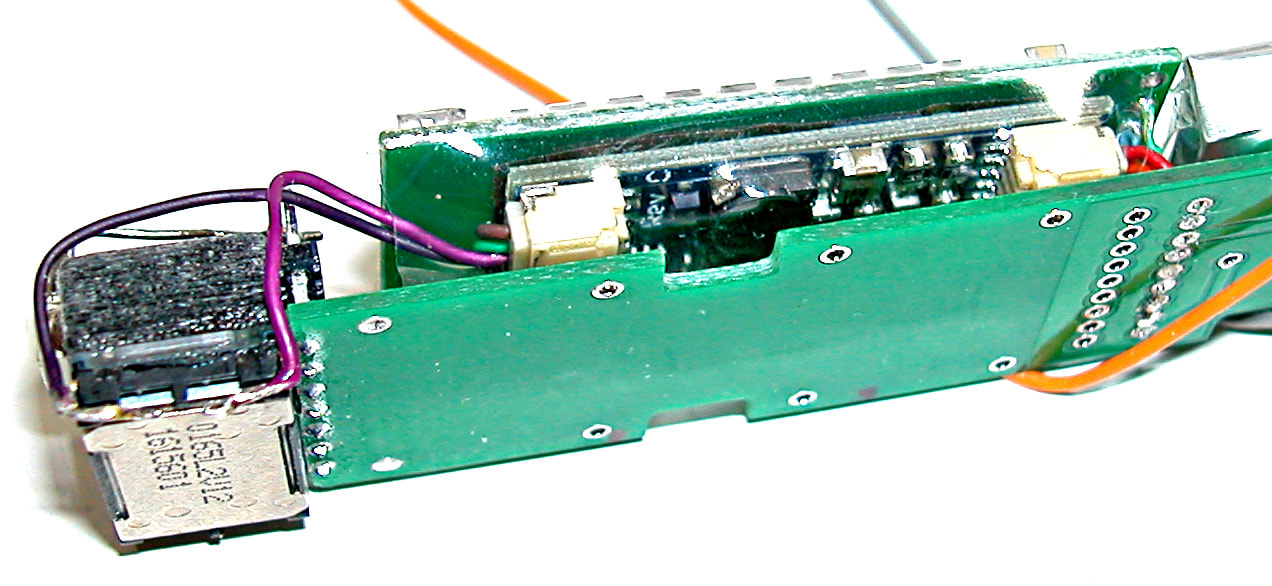

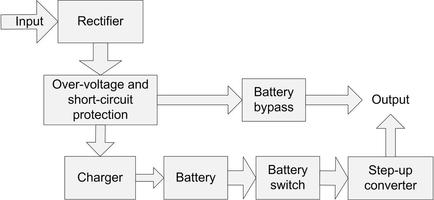

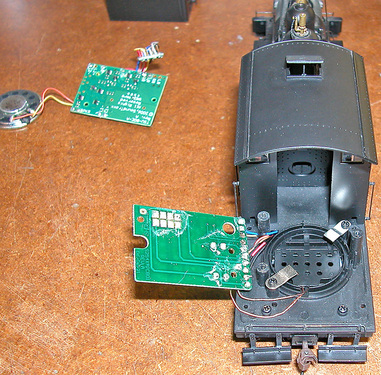

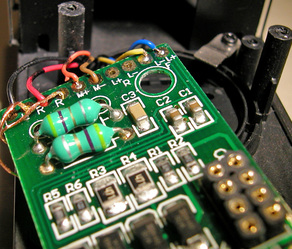

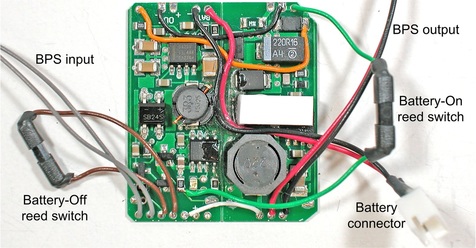

| Blunami circuit board looks like a TSU-2000 except for the addition of a small radio receiver produced by a company called U-Blox. As SoundTraxx explains, if no Bluetooth radio signal is detected, Blunami can be controlled by track DCC. If BT radio is detected, track DCC is replaced by BT communication. |

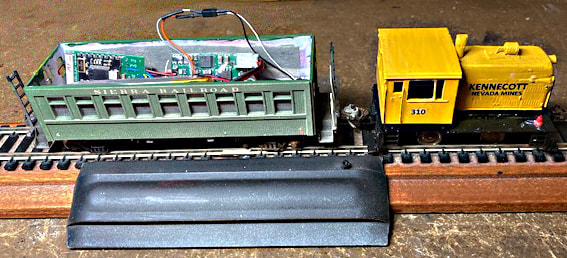

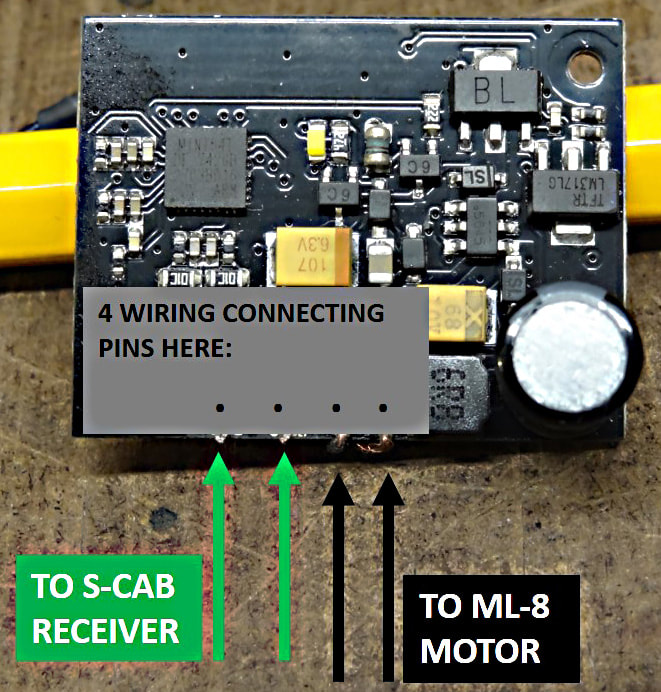

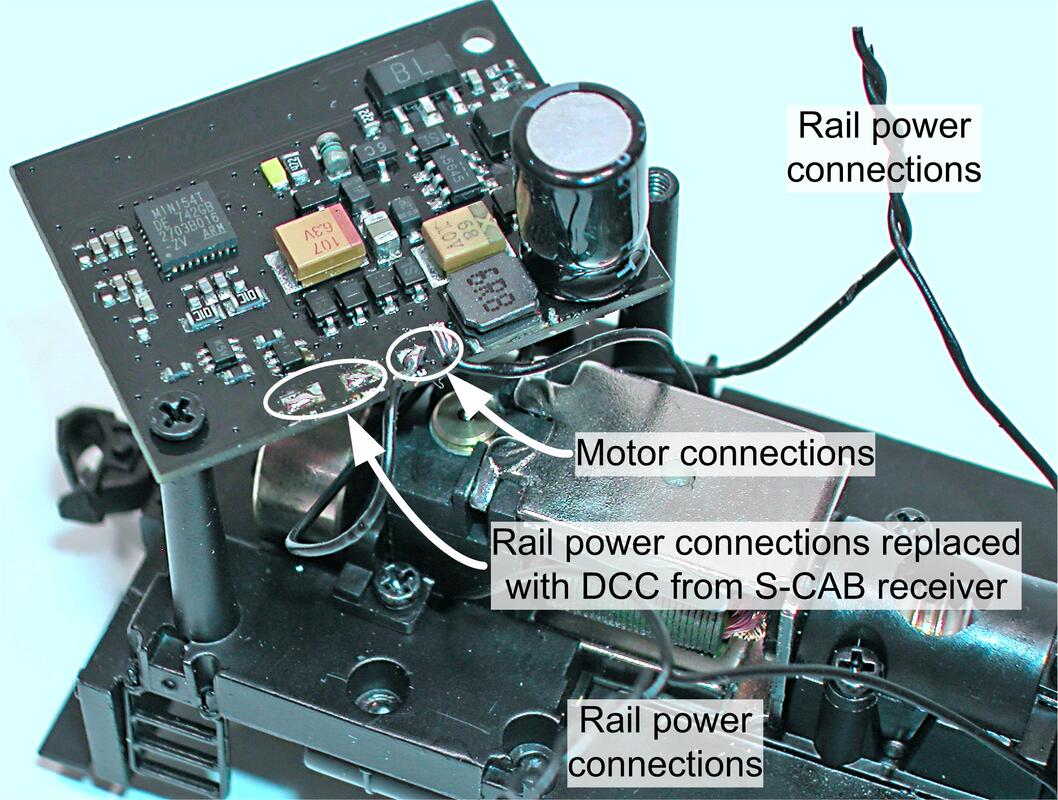

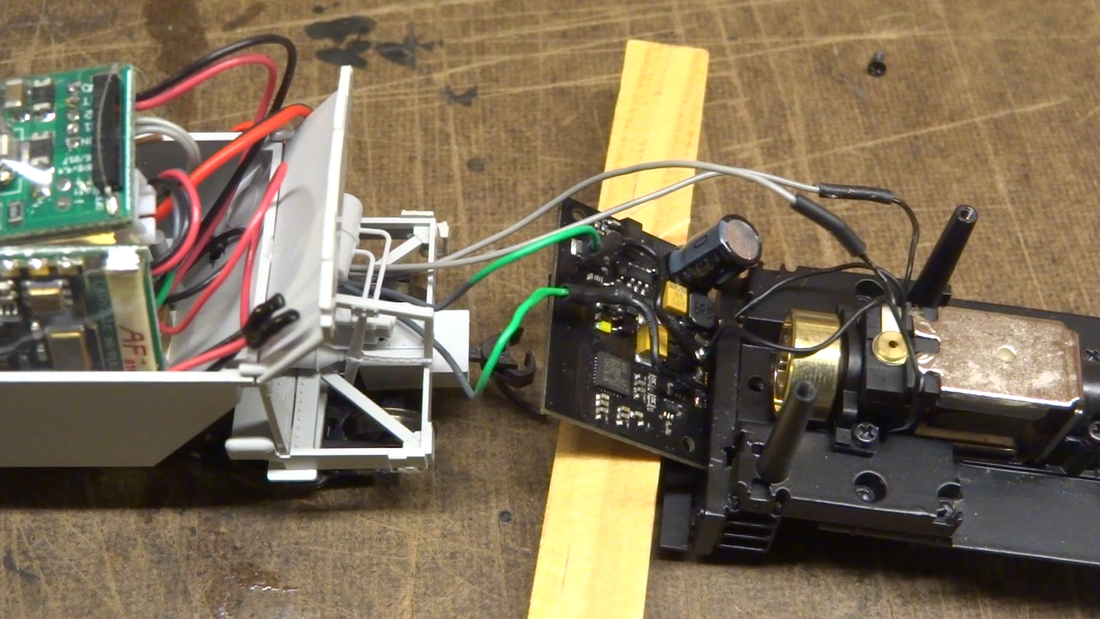

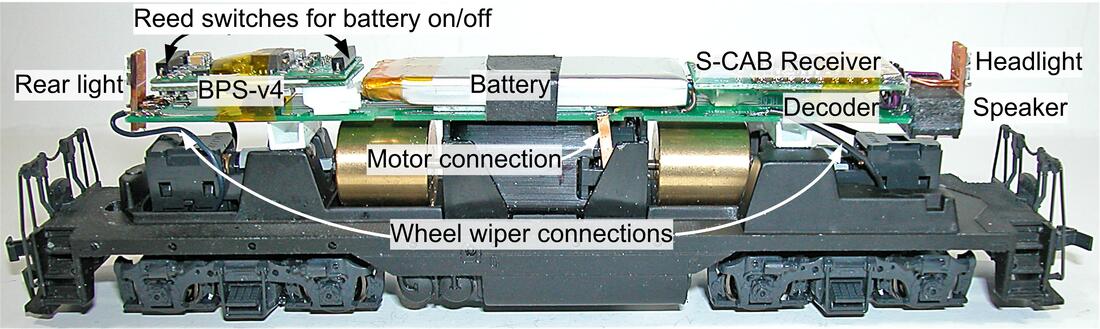

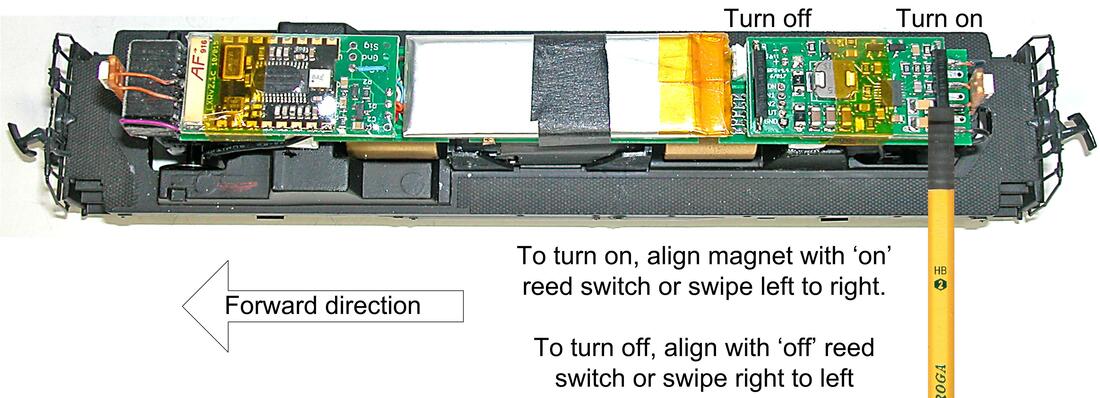

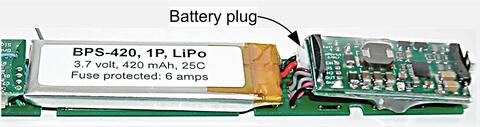

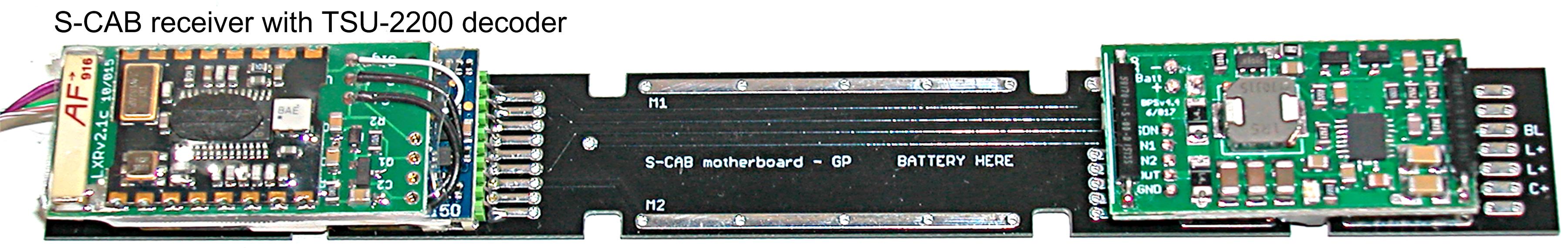

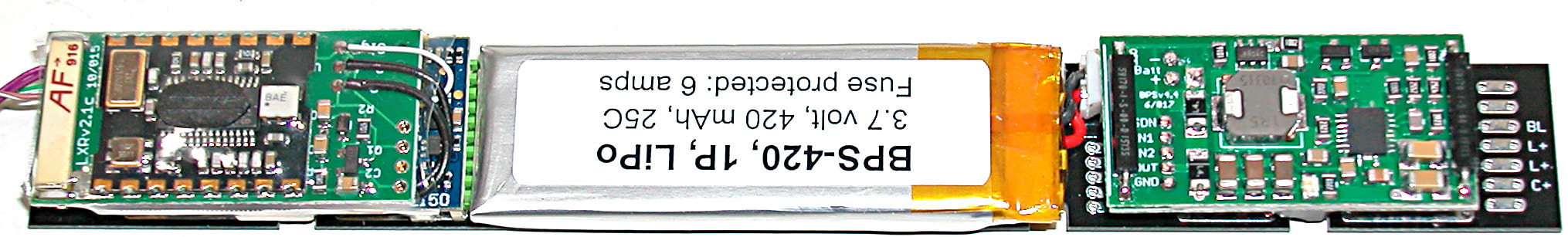

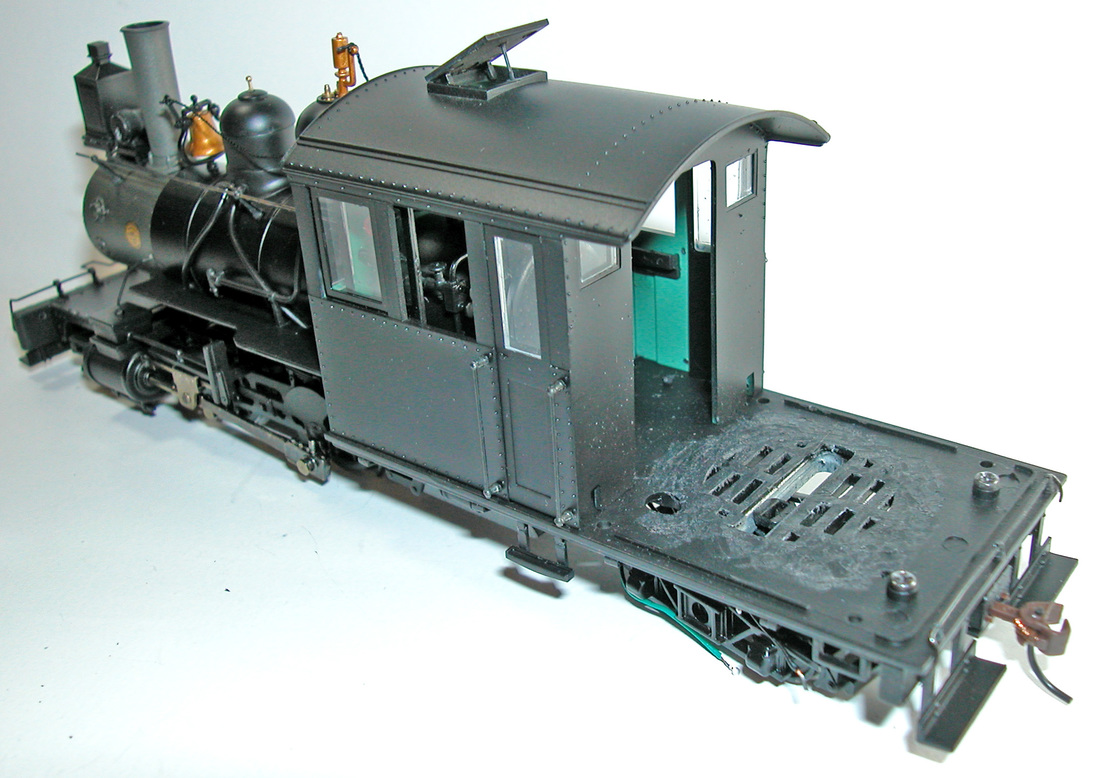

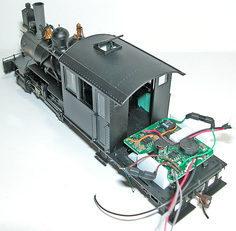

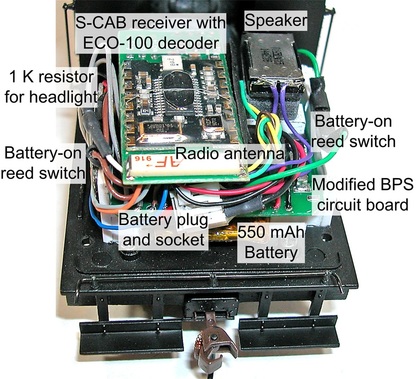

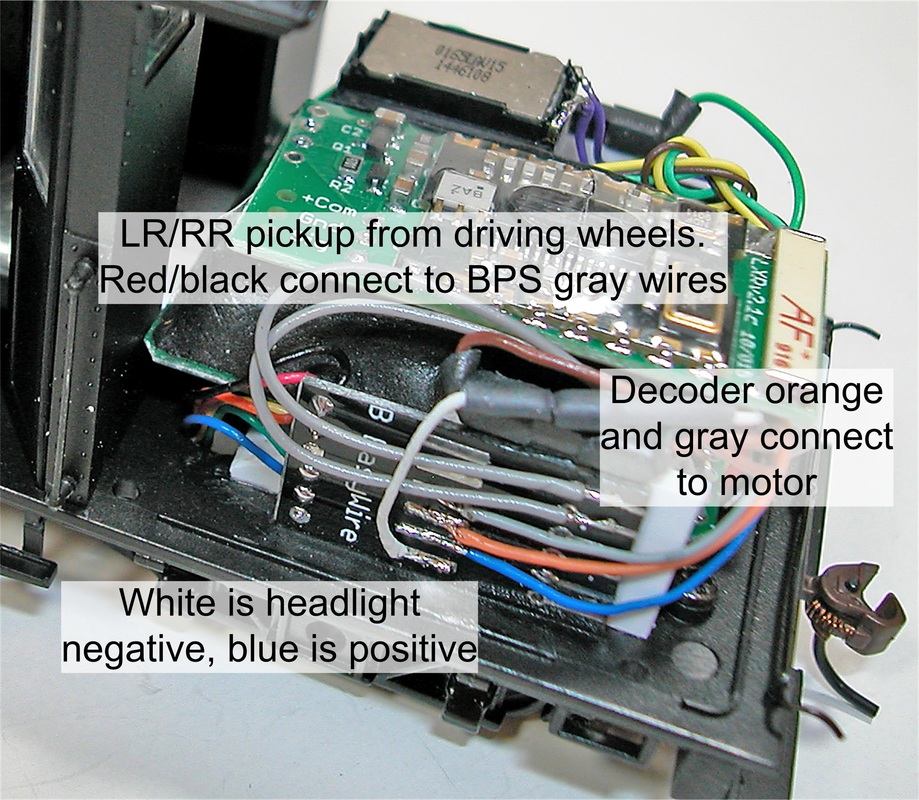

Adding S-CAB Radio

Similar to TSU-2200, Blunami should treat S-CAB radio input as if it is track DCC. The two radios work at different frequencies, so radio interference is not a problem and BT should prevail if both are detected, just as it does for track DCC.

Testing

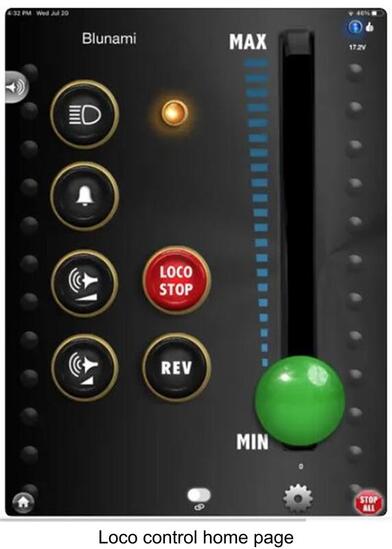

- The answer was yes. The iPad app connected when decoder battery power was turned on.

- Decoder data was displayed and there was an opportunity to enter loco name and define a few loco characteristics.

- Control commands worked.

- Decoder CVs could be viewed and edited.

- The iPad app saved decoder data.

- When S-CAB throttle was turned on, nothing happened. S-CAB commands were ignored and iPad commands continued to work without problem, as specified.

- When iPad was turned off, S-CAB did not automatically take control of the decoder.

- However, S-CAB throttle did gain control when the Blunami was rebooted (power off, then on).

- When Blunami app. was turned on, it eventually connected and took control away from S-CAB.

Working with iPad App

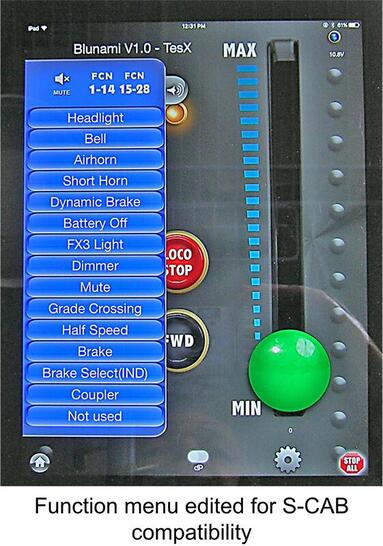

Function tabs are accessed as a slide-out menu from left side of the loco control home page. An additional swipe right drags a duplicate set of editable tabs into view.

Bill was not concerned by loss of RPM+ and RPM-. These tabs alter sound to simulate prime mover speed changes, but do not affect loco motion.

All CV programming to change function mapping was done with the Blunami app.