Since this is a medium sized steam loco with a good-sized tender, conversion to radio control and battery power looks a relatively straightforward project. Modelers familiar with Bachmann products will be aware of phrases such as "DCC-ready", DCC On-Board" and I can now add a new one; "DCC not ready". I suspect this loco is a relatively recent release of what appears to be an old design. It's clear that DCC was not considered when producing this product.

Loco Modifications

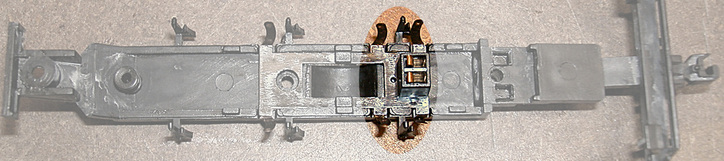

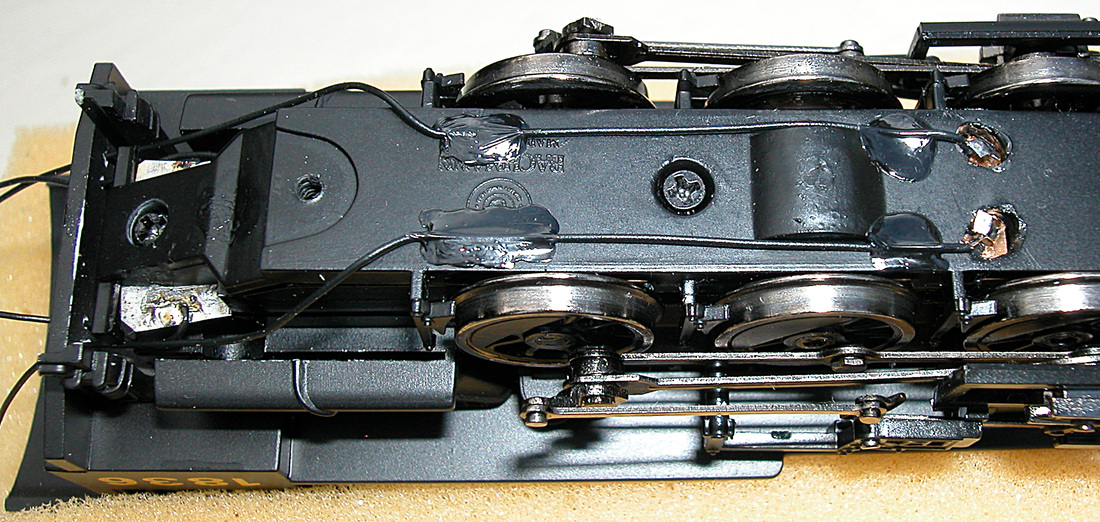

Most of the project involved the tender, which I'll discuss later, but the engine was the real drama. Its design is conventional; a split-frame metal chassis with the rest of the model mostly plastic. Right and left-half frames are electrically separated and measurements indicate that motor terminals are connected to each half-frame. Fortunately, rail pick-up via driver wheels is insulated from the loco frame and rail power is routed to the motor through phosphor bronze contacts between wheel wiper assembly and frame halves; highlighted below.

A cardinal rule of decoder installation is isolate the motor terminals from everything except decoder motor output (orange and gray wires). There must be someone in the world who knows how to remove this loco's body and get access to its motor. Removing the bottom cover plate (in photo above) allows wheels to drop from the chassis but valve-gear is still attached to the rest of the loco. Taking the valve gear apart is often a path of no return and all other options risked serious damage to a brand new loco. Without access to the motor, the only option is leave the motor connected to loco frame.

| If contacts highlighted in the photo above are removed, rail power pick-ups are isolated from the loco frame. There is a remote possibility that derailment or some other accident could somehow short the frame through rail contact, but it is very unlikely given the construction of this model. In other words, there is negligible risk leaving motor terminals connected to chassis half-frames so long as the chassis is disconnected from rail pick-up. |

In fact, the contacts were not removed, but simply reversed and brought through holes drilled in the bottom cover so rail pick-up is wired to the tender where track power is used by the BPS for battery charging.

Connection from decoder to motor must be through the loco frame. For this, two brass shims were added and held in place by the bottom cover.

The Tender

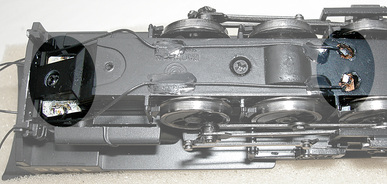

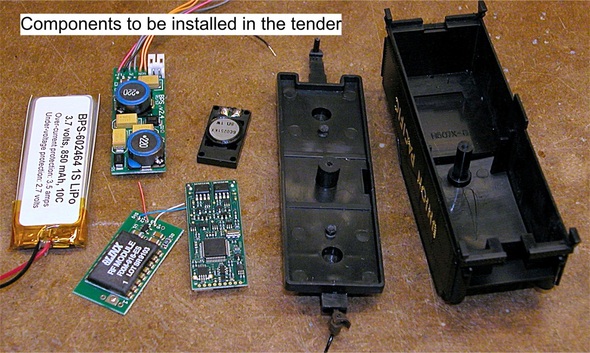

| A single screw holds the tender together, but it's center screw mounting must be removed to open space for electronic components. As a result, we need an alternative method for reassembly. The new arrangement holds the base with tabs added at the left end in the photo and, on the right, screws into styrene blocks glued at the loco end of the tender shell. |

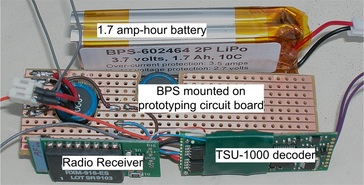

Installation

Once obstructions are cleared from the tender, installation follows a familiar arrangement with BPS and its magnetic sensor flush against the top of the tender. By mounting the decoder and radio receiver on edge against the side of the tender, there is room for a double-size battery. The only compromise is a smaller, low profile speaker, which fits on the tender floor below the battery. It's an acceptable trade-off. A larger speaker would only provide marginal improvement in sound quality, whereas the larger battery doubles loco operating time on battery power.

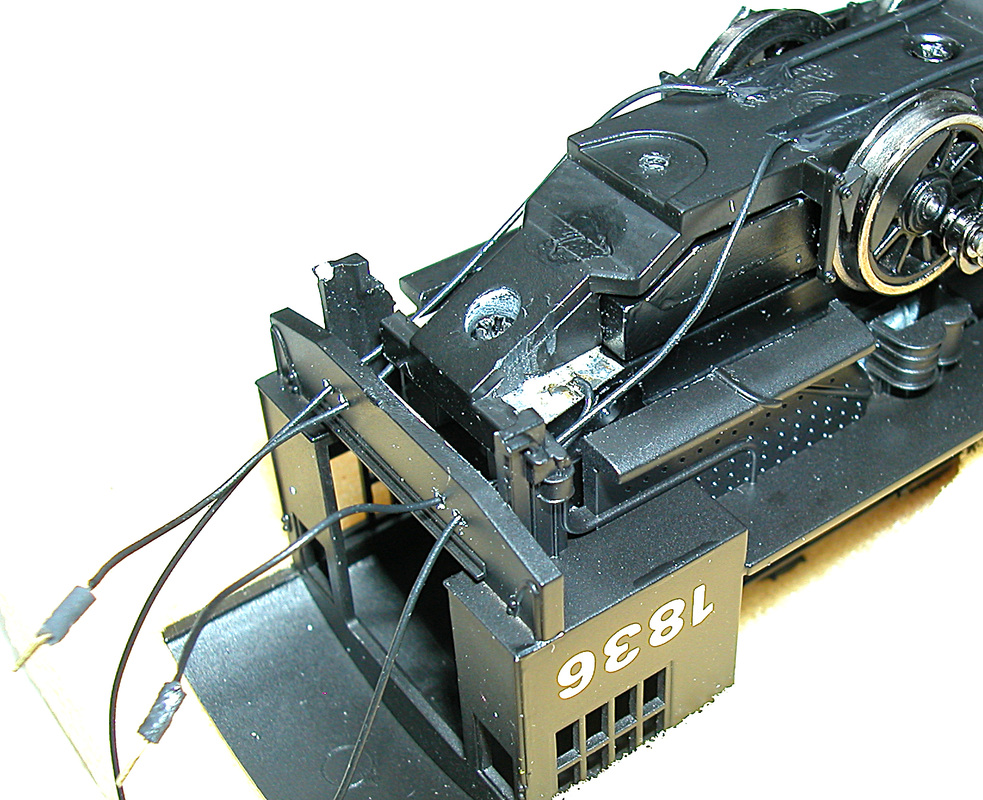

Here are some close up views of wiring between engine and tender. The loco's headlight is not accessible and is factory wired in parallel with the motor. This leaves 4 wires; 2 motor connections and 2 for left/right power pickup.

| Miniature plugs and sockets allow the tender to be disconnected from the engine but the effort is not convenient and should rarely be necessary. I replaced plastic wheels on tender trucks with metal and considered adding wipers for power pick-up. However, wheel wipers on the loco drivers are nicely engineered and likely to be more reliable, justifying the extra wires between engine and tender. |

Conclusion

The owner allowed me a few days to operate this loco after its conversion. The result is quite convincing, both with respect to performance and sound. I programmed decoder momentum settings consistent with this type of loco and limited the model's maximum speed. This makes loco exhaust more realistic and, to my ear, the small, low profile speaker provides excellent sound. As with operation of a real loco, the engineer needs to think ahead and anticipate braking distance. There is, of course, the totally unrealistic emergency stop initiated by the 'Halt" button.

Despite my earlier complaints about this model's readiness for radio control and battery power, I see real value in working with an economical product to achieve the same results as models three and four times its price.