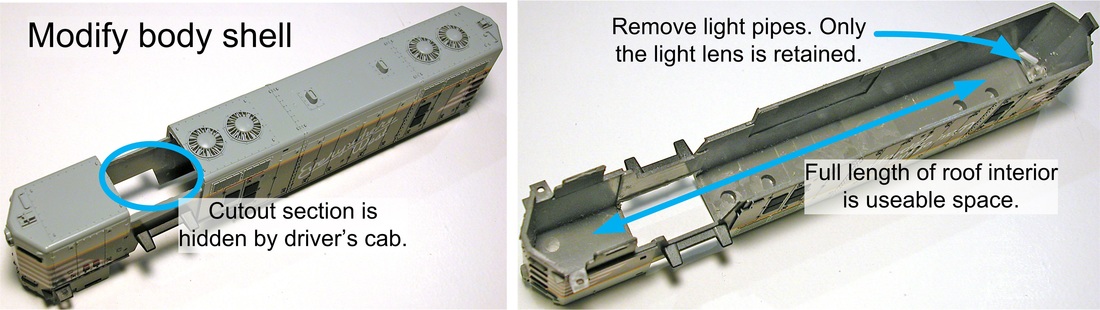

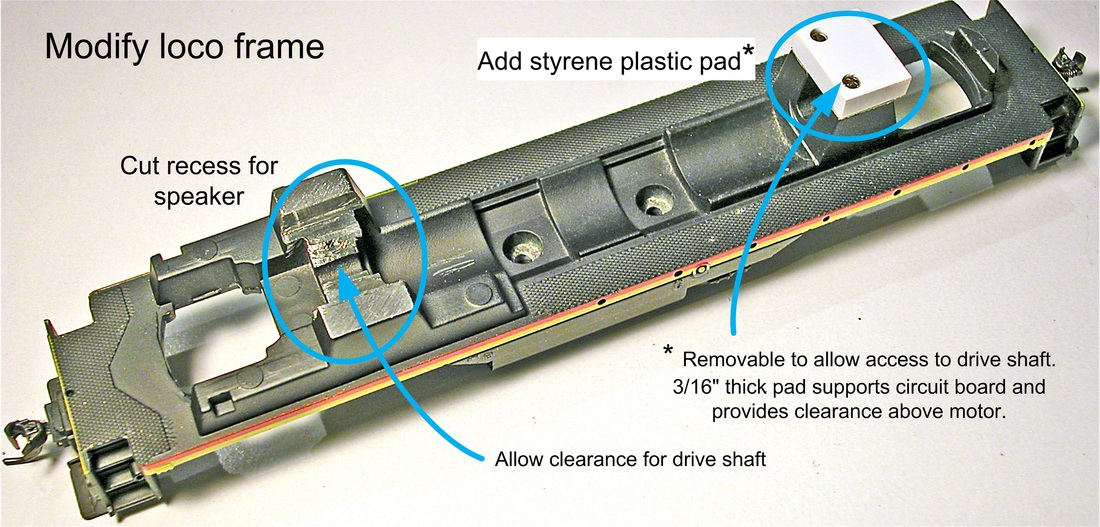

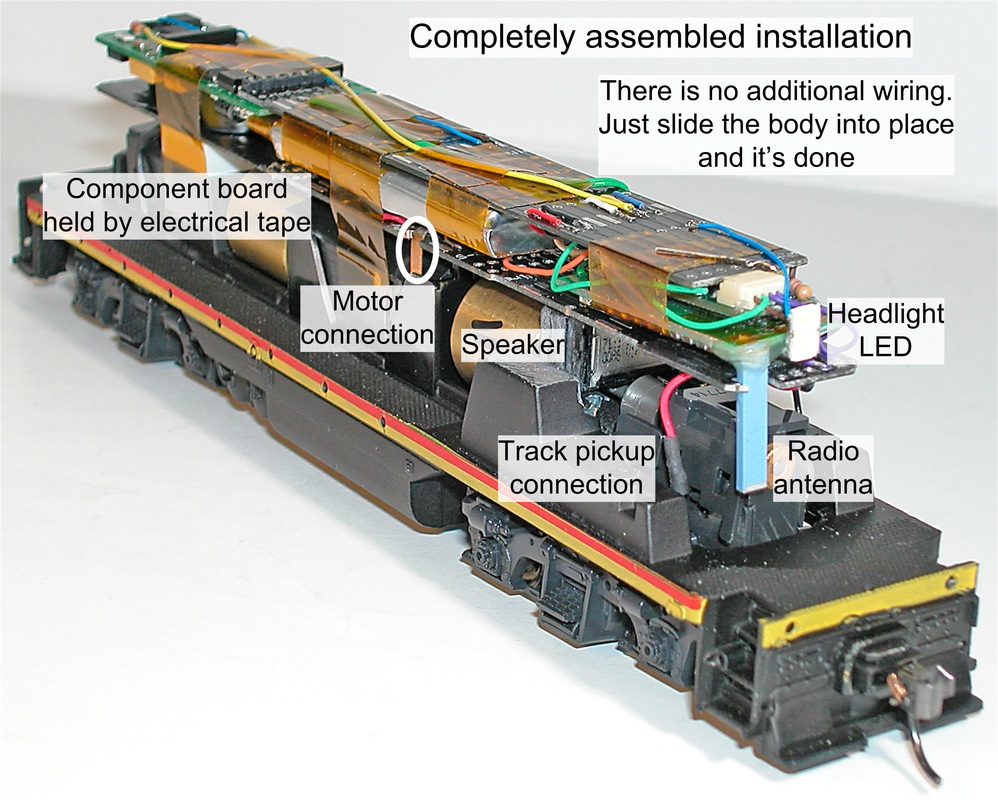

Introduced 1987-89, these models, which were manufactured by Kato and sold by Atlas, have excellent mechanisms and are great candidates for S-CAB battery power and radio control. The cast metal frame is heavy enough for traction, but leaves space above the motor for electronics and battery. With some careful trimming of the body shell, this space can be extended the full length of the loco. The completed installation (photo left) shows no evidence of any modification to the loco.

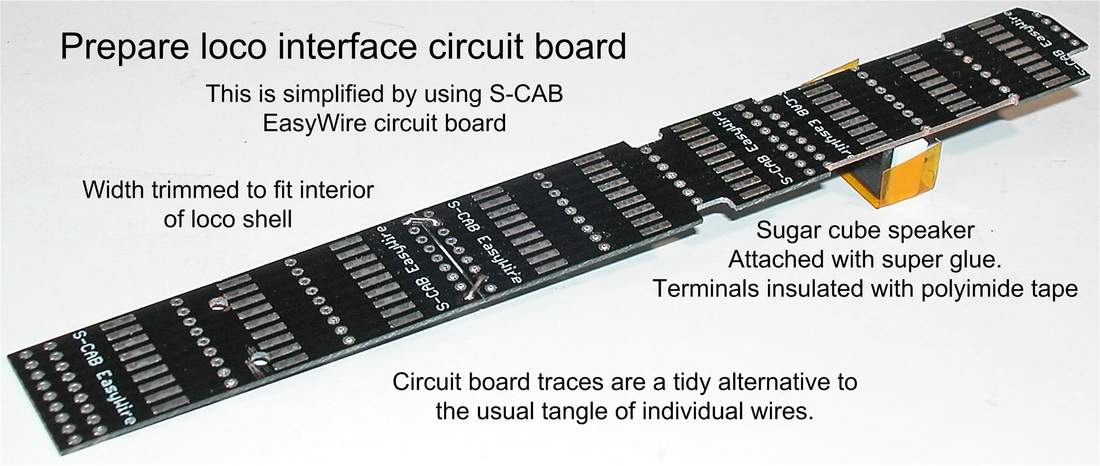

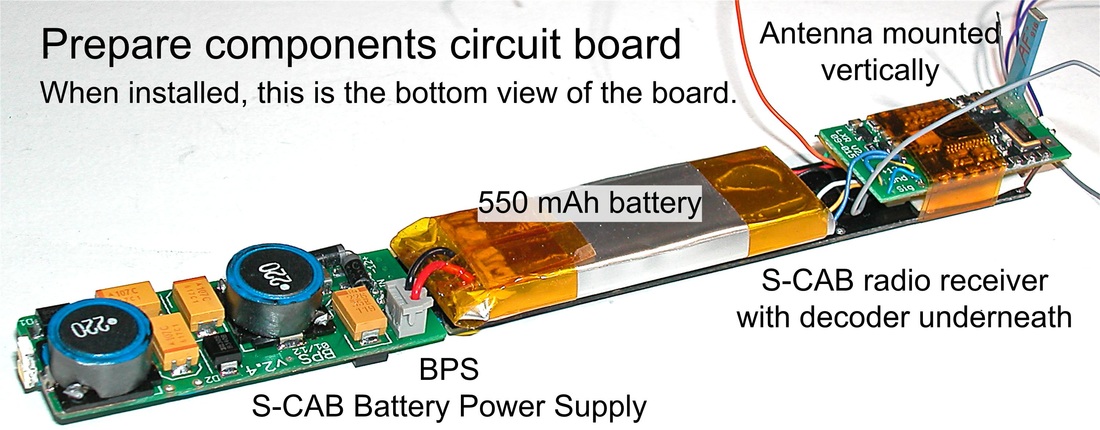

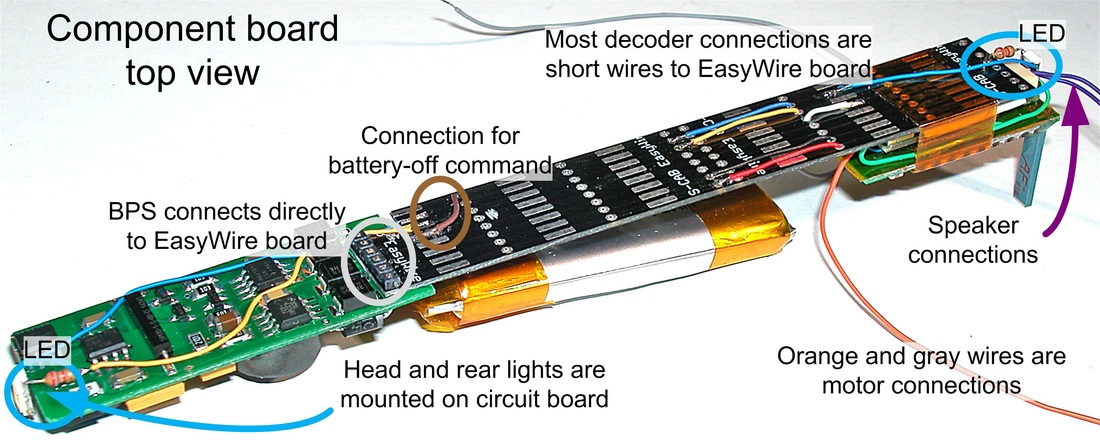

This description illustrates use of a circuit board (sometimes called a "motherboard") to simplify installation and complete as much work and testing as possible on the workbench. Wiring within the loco is minimized by mounting front and rear lights on the components circuit board. As a result, there are no wires connected to the body shell, which can be removed and replaced without restriction. The project involves modification of the loco body and frame, assembly and test of two subsystems and finally, installation.

Loco Modifications

Subsystems

Assembly

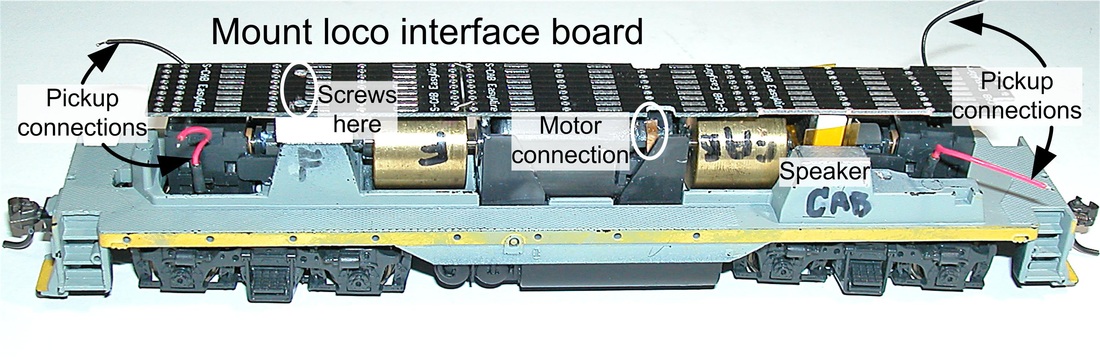

Traces on the loco interface circuit board are used for rail pickup connections to front and rear trucks. If convenient, motor connections can also be to this board, which makes a total of 6 wires (2 to each truck and 2 to the motor) to be disconnected should it ever be necessary to remove motor or trucks.

The component board sits on top of the interface board and is held in place by electrical tape.

Since LED lights are mounted on the components board, there are no connections to the loco body, which simply slips into place to complete the installation.