Introduction

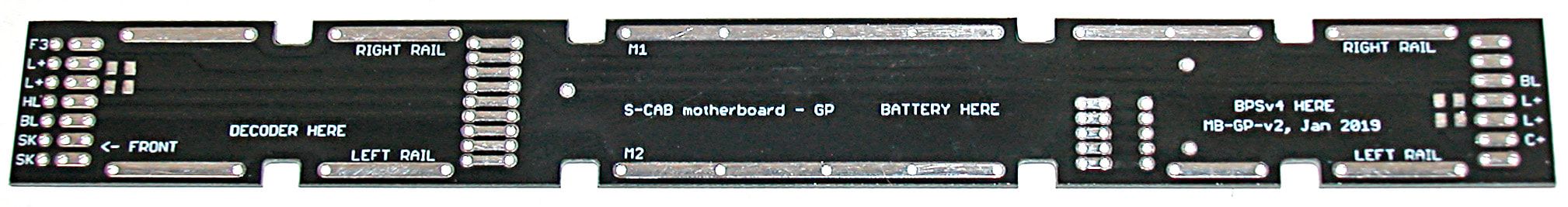

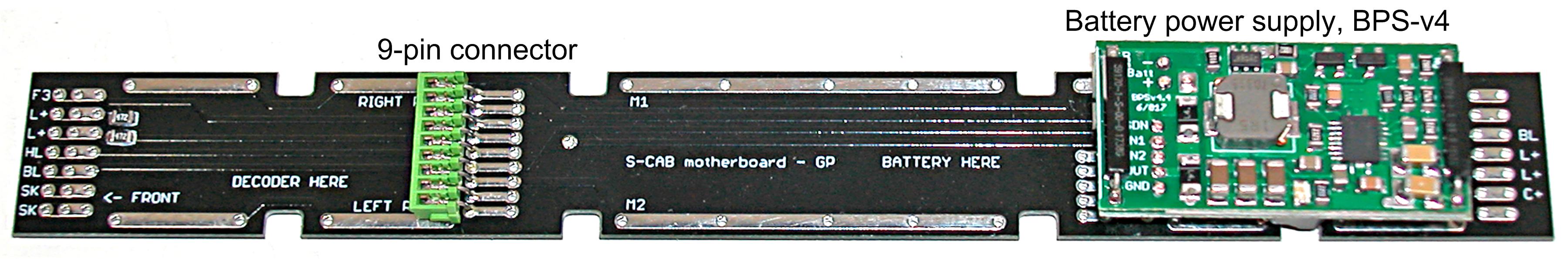

The motherboard concept has been discussed elsewhere. It is intended to simplify installation of an S-CAB battery powered, radio-controlled system in small-scale locos. The purpose of this document is to report its application in a HO-scale Atlas-Kato GP-7. For brevity, we’ll skip the details and go directly to the result.

Ready to roll

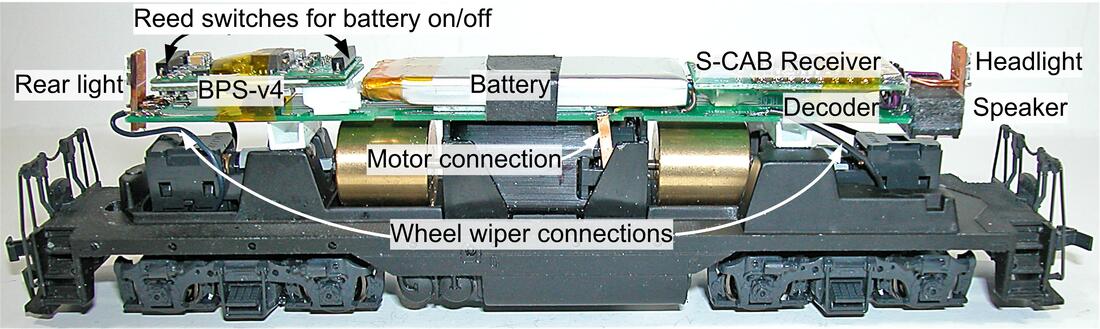

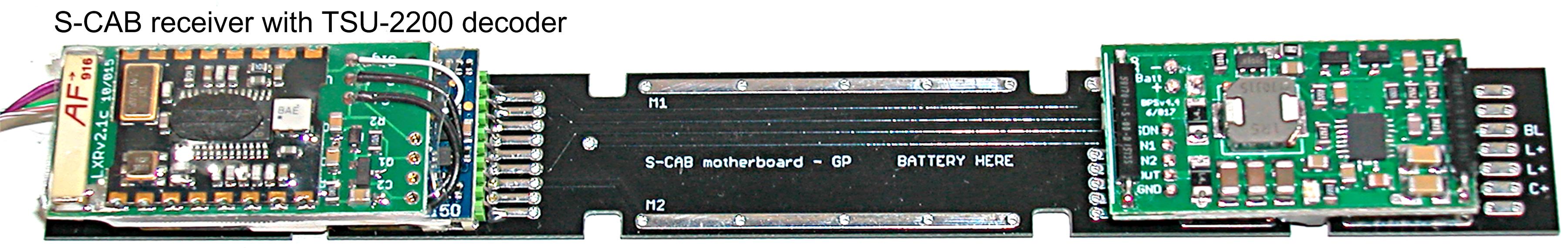

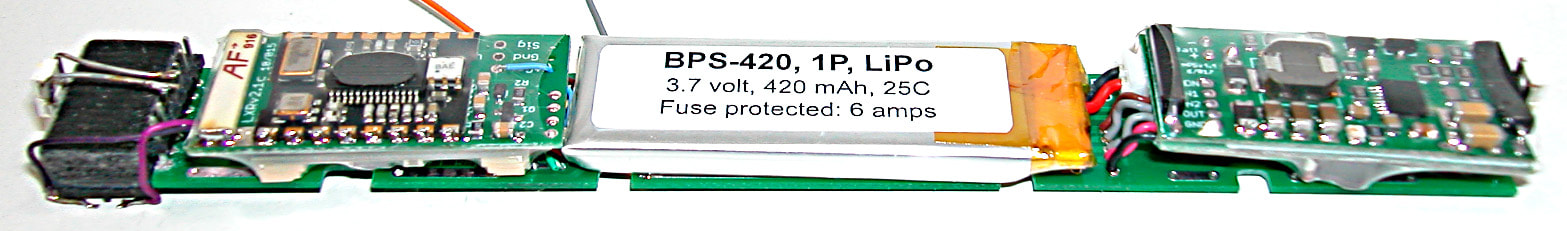

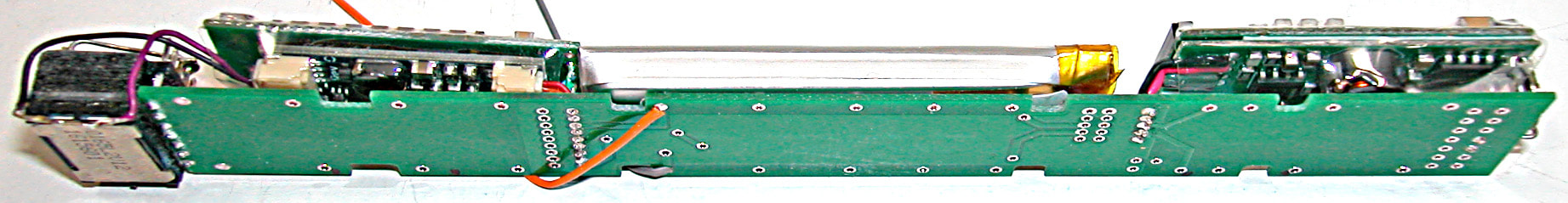

This loco is ready to roll. All it needs is a body shell, which slides over the installation onto the chassis without much effort. It’s shown naked and annotated as an introduction to use of an S-CAB motherboard.

For this installation, all components are mounted on the motherboard, including loco’s lights. This arrangement is a convenient characteristic of a GP-7 and other high-nose diesels. Consequently, no wiring connects to the body shell.

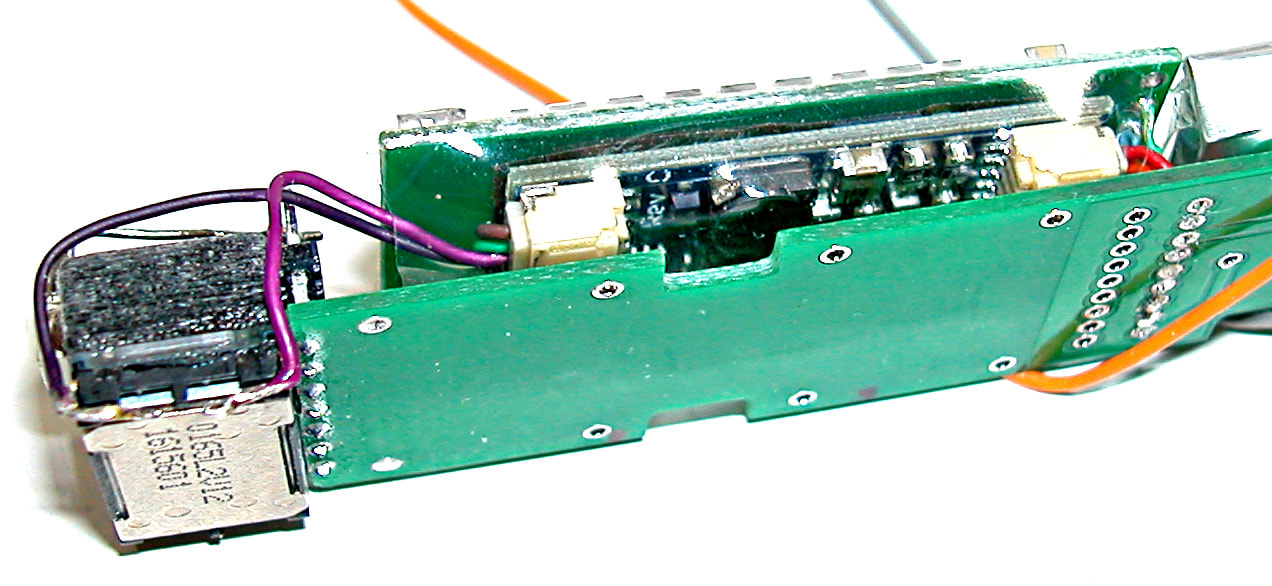

The motherboard assembly is completed and tested on the workbench. It is then mounted on the loco chassis and permanent connections made to motor and truck wheel wipers. Additional tests are completed before replacing the body shell. For example, does the forward direction command cause forward motion and operate the headlight.

Testing

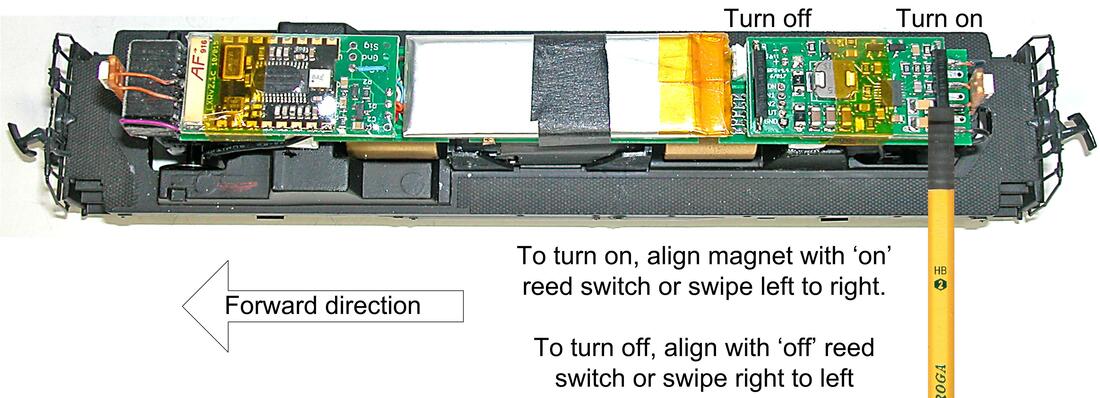

No need to replace the body shell for a work-bench test-run. No need for track or power. Just turn on BPS battery power using a magnet wand and the loco (with or without shell) is ready to roll but be careful it does not end up on the floor.

Aside from running off bench-top, this is a low-risk test. The motherboard was tested before making chassis connections and there is no external power source to cause trouble.

A track test is higher risk. First, try it with no track power, which is not much different from a bench test, except the loco can be operated more thoroughly if its battery has enough charge. To test battery charging, turn on track power. This is the step where serious trouble can occur, which is a good reason to do it without the body shell. Common mistakes are forgetting to isolate motor terminals from loco frame, bad choice of power supply, shorted truck wipers, etc.

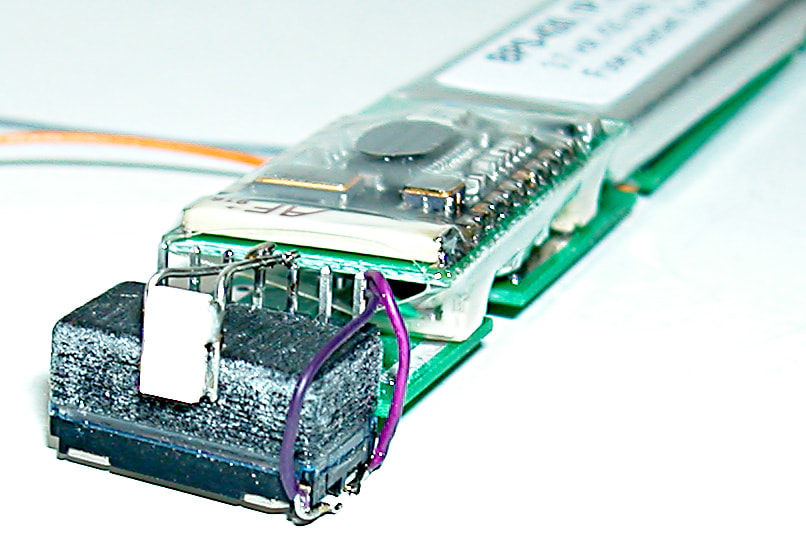

A green LED on BPS-v4 indicates if battery is charging. It's not obvious because the green LED is on the underside when BPS is mounted on the motherboard. The BPS is oriented so that reed switches are topside where they can be activated by a magnet wand. Another good test is turn off battery power (blue LED off) before turning on track power. BPS starts automatically when track power turns on.

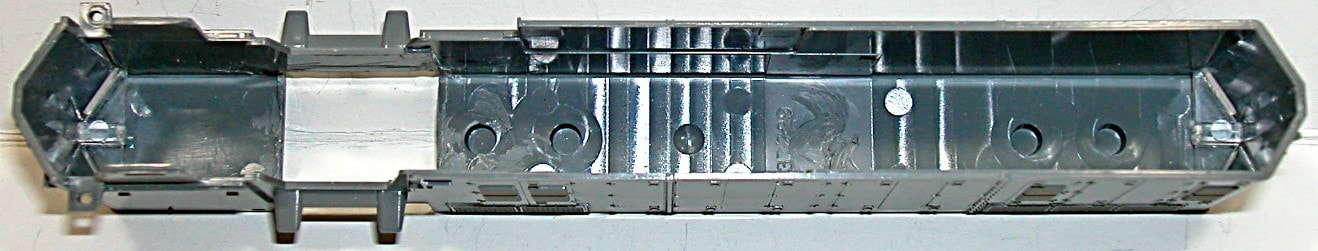

Replacing body

This is a critical step in any installation. Will the lid close? The motherboard helps by enabling test fitting more easily throughout the project. Wiring clutter is eliminated, components don’t rearrange themselves by accident, and tight spots inside body shell can often be trimmed. The most difficult issue is headroom. Is there enough clearance above the loco’s mechanism for the motherboard assembly? This question must be addressed when planning an installation.

Done

Good news. The lid fits.

Motherboard Assembly

The following components are mounted on the motherboard:

- BPS-v4: Provides 11 volt power supply from 3.7 volt LiPo battery. Includes battery charging from track or other external power

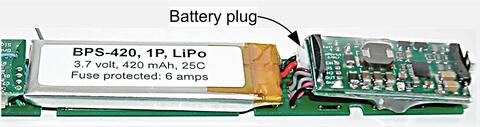

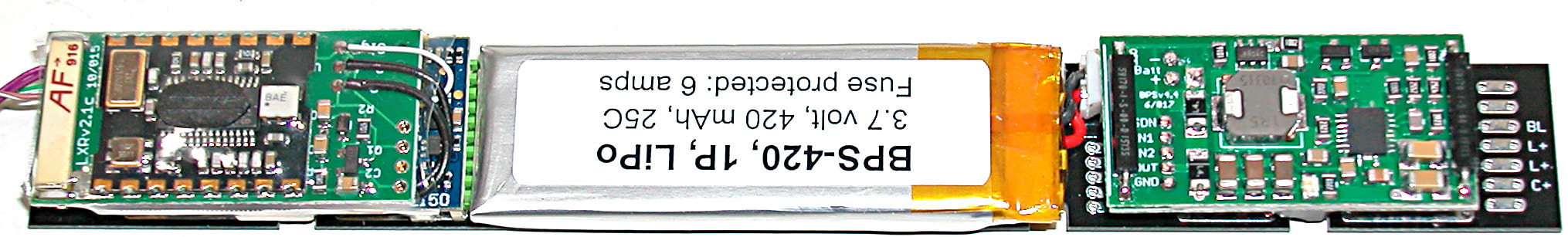

- Battery: A 1P-420 LiPo cell with integrated 6 amp fuse

- Sound Decoder: A SoundTraxx TSU-1100 sound decoder

- Radio receiver: An S-CAB radio receiver integrated with decoder

- Speaker: A 1 watt mini-cube

- Head and rear lights: Surface mount LEDs with 4700 ohm resistor

Maintenance

Battery replacement: The battery is best secured to the motherboard by a removable method that does not leave a mess to clean up. Kapton tape is good and leaves no residue. Double sided adhesive tape is not recommended. When freed, lift the battery and lever its plug from BPS socket with tweezers or needle nose pliers. Since the battery leads are deliberately short (about ¾”) and the plug is tight, pulling by the battery may remove the battery and leave its plug stuck in BPS socket.

If the loco’s mechanism needs maintenance, unsolder motor and truck pickup connections from the motherboard. If glued in place, there are 2 locations to pry loose and the assembly lifts off as a unit. If held in place by Kapton tape (author’s preference), cut and/or peel off the tape to remove the assembly.

Conclusion

This installation was performed by John Lloyd in four identical models for a Canadian customer. The motherboard was designed to fit the GP-7 as well as a popular selection of North American diesel-electric locomotives. EMD GP, F and E class locos are good candidates. As we gain experience, the motherboard may be provided as basic, partial and fully assembled versions.