Project

Two new Walthers ALCO DL-109 HO-scale locos will be converted to S-CAB radio control and battery power for operation as a permanent consist with number 759 as the lead loco (the A unit) and 749 (B unit) running backwards. An identical set of components will be installed in each loco and the 2-loco consist will be operated by giving each loco the same decoder address.

Planning

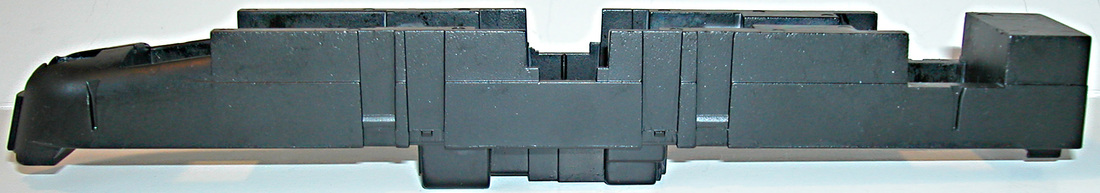

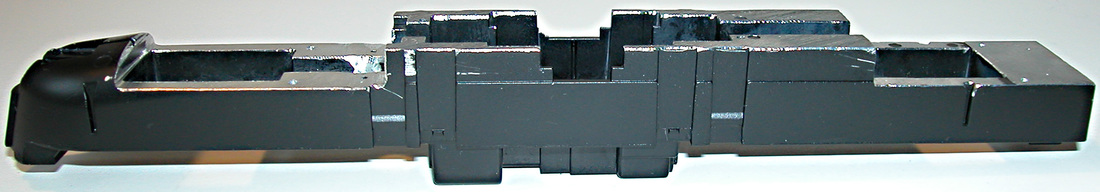

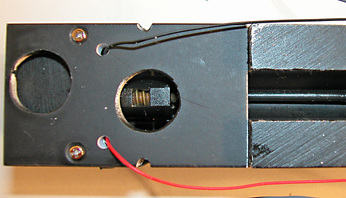

When buying locos for S-CAB installations, it's best to avoid factory-installed decoders and we begin this project with a "DC version" Walthers model. Although it is marketed as DCC ready, this loco is not DCC friendly. A circuit board to accommodate a decoder is provided above the motor, but there is very little clearance between a large metal casting that forms the model's frame and the underside of the loco's roof. Removing part of this casting is the only way to create space for battery and radio components. This requires complete dis-assembly of the loco and, although this may seem like a lot of work, it's not very difficult and provides a more orderly way to perform an installation. The mass of metal that forms the loco frame is photographed below.

Modifying the loco frame

There are only three locations where removing metal can provide useful space:

- Above the motor, but not lower than the top of the motor, provides an extra 1/8" clearance

- Above the front truck and drive shaft, while leaving clearance for the truck to swivel and tilt freely

- Above the rear truck and drive shaft, while leaving clearance for the truck to swivel and tilt freely

Selecting components

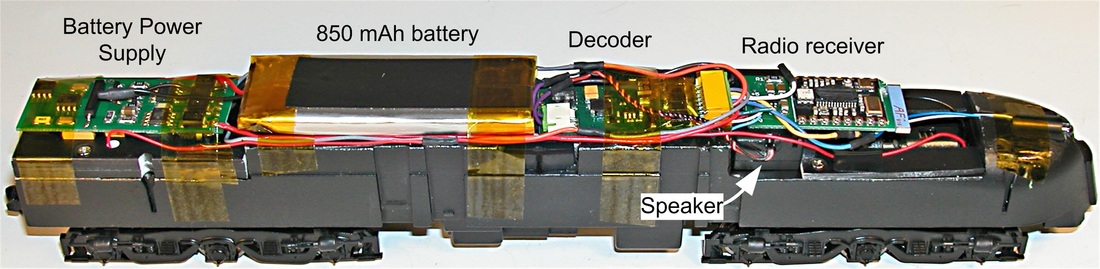

There are five components to install, three of which significantly affect space requirements. The BPS circuit board is fixed and the TSU-1000 decoder is required to safely handle power requirements of this heavy loco. This leaves battery, radio receiver and speaker for which we have options.

| Highest priority is the battery. It is the largest component and determines operating duration between recharges. Since small speakers in well-designed enclosures provide good sound quality, it is a good trade-off to make speaker size our second priority. Radio receiver size can be modified by antenna choice and orientation. | Final Selection: S-CAB battery power supply, BPS BPS battery, 850 mAh LiPo Decoder, TSU-1000, model 827104 Speaker, Railmaster, DS1425-8 S-CAB receiver, cross-wise mounted antenna |

Arranging components

Here are a few considerations that led to the final arrangement illustrated below.

- For good radio reception, avoid placing the radio antenna against a metal surface.

- The BPS turn-on sensor must be outside the range of magnetic fields created by motor and speaker.

- The speaker should be located so that the motor magnet does not interfere with speaker performance.

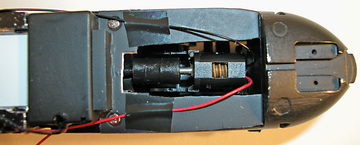

The radio receiver is mounted at front of loco and part of the frame is cut away for two reasons:

The speaker is glued to a styrene plastic mounting that is attached to the frame with screws, which allows assembly to be removed for access to drive shaft and front truck. To complete this sub-assembly, the radio receiver will be mounted on back of speaker enclosure with adhesive or double sided sticky tape.

- To accommodate the speaker

- To create some air-space between antenna and metal frame.

The speaker is glued to a styrene plastic mounting that is attached to the frame with screws, which allows assembly to be removed for access to drive shaft and front truck. To complete this sub-assembly, the radio receiver will be mounted on back of speaker enclosure with adhesive or double sided sticky tape.

The BPS is installed at the rear of the loco where it sits in a plastic mounting attached to the loco frame with screws so that the rear truck is accessible. By using 1/8" styrene, the two largest BPS components (inductors) are almost flush with the lower surface of the plastic mounting. There is also a spacer below the mounting so that the BPS magnet sensor is positioned close to the loco roof.

This arrangement leaves space above the motor for battery and decoder, neither of which is sensitive to the motor's magnet.

This arrangement leaves space above the motor for battery and decoder, neither of which is sensitive to the motor's magnet.

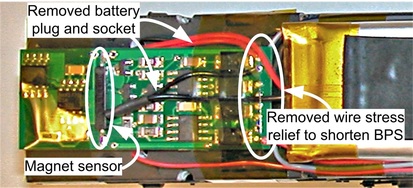

Tweaks to reduce component size

The BPS is delivered with holes for wire stress relief to prevent breaks at soldered connections, but this precaution can be abandoned to shorten the circuit board by about 1/8".

Eliminating battery socket and direct wiring the battery connection is another space saver. Wire both battery and BPS with leads an inch or more in length, then solder and insulate to join leads as the last step in making the connection. This reduces the risk of accidental short-circuit while working with a charged battery and also provides extra wire to simplify battery replacement, should this become necessary.

Tweaks to fit components in available space

| S-CAB receivers are normally bundled back-to-back with the decoder, but an end-to-end arrangement fits more conveniently in this loco. Receiver and decoder are close together for this installation, but there is no limit to the length of wire between receiver and decoder. | Although the antenna cannot be separated from the receiver circuit board, there is a selection of different antennas and some can be oriented to suit the available space. This installation uses a ceramic chip antenna mounted "cross-wise". |

Completing the project

There is nothing quite as frustrating as completing, testing and tidying up wiring, only to discover the loco's body shell will not fit with everything installed. To avoid this disappointment, it's best to perform several trial fits of the shell with various combinations of components temporarily held in place with electrical or Kapton tape.

Components should be bench tested before installation and retested as each subsystem is installed and wired. This includes a test to be sure motor polarity is wired correctly and noting for this installation that loco 749 will be running backwards when the consist is operating in forward direction. It is therefore convenient to wire its motor with reversed polarity relative to the lead loco (759).

Setting up the consist

As mentioned earlier, locos will be coupled back-to-back to form a more or less permanent consist. Since the locos are mechanically identical and their speed characteristics are similar in each direction, no speed curve matching is required and respective motor control CVs will have identical values. Configuring function outputs is easy, since a headlight (function F0) is the only loco feature to be controlled. One other function output, F5, will be used to turn off battery power.

Assigning the same decoder address to each loco, avoids the need for a separate consist address. Each loco's decoder, having the same address, will respond to a radio command for that address. The only reason to set up a consist address is a requirement for each loco to respond differently to the same command. This also applies to CV programming commands and is the reason loco 749's motor was connected with polarity reversed; it runs backwards in response to a forward command. A similar result could be achieved using CV29, but this requires the decoders to have different values for CV29. Except for the bell (which is set to zero volume in 749), both locos have identical values for all CVs.

With radio control, no programming track is required and, once the decoders have the same address, CVs are programmed simultaneously for both locos, using either operation or service mode programming. To set a CV value (for example, the bell volume) for only one of the locos, just turn off the other's battery power. If using service mode programming, be sure to turn off power for all other decoders to prevent them from responding to a globally addressed command.

To separate the consist and operate as separate locos, the S-CAB throttle can be used to change the address for one of the locos. If desired, CV29 can be programmed (using the S-CAB throttle) to reverse motor polarity of loco 749.

Operation

The consist is operated in the same manner as a single loco. Momentum settings should be the same for each loco with values that match acceleration and braking somewhat realistically with diesel engine exhaust sound. This can be done by using the S-CAB throttle to adjust the values of CVs 3 and 4.

Except for one operating scenario, decoder default settings operate headlights automatically. F0 toggles headlights on and off. With F0 on and loco 759 moving forward, its headlight will be on and 749's will be off. However, if the consist is backing a train into a station or siding, 749 will be shining its headlight onto the end of the nearest car. Operation will be a little more realistic if F0 is used to turn off headlights.

Battery power requires a method to turn batteries on and off. If the consist is on powered track, turn-on is automatic when BPS detects track voltage. If track is not powered, a magnet held close to the on-board sensor turns the battery on manually. With some wired connections between locos, both could be turned on using one loco's sensor. However, it's simpler to just turn on each loco separately (so long as we remember to do it).

If there is no track power, a decoder F5 command turns off batteries of both locos (since their decoders have the same address). Function commands toggle decoder outputs on and off. It may not seem intuitive, but turning F5 on, turns battery power off. However, the presence of track voltage overrides decoder F5 output and keeps battery power on. This can be the basis of a useful procedure as follows.

| At the conclusion of an operating session, the consist (or loco) is parked on a siding with track power to charge the battery and with F5 turned on. If later, the loco being charged is forgotten and track power turned off, F5 will immediately turn off loco batteries and prevent slow discharge from draining the battery. With battery power off, all loco electronics shut down, including the decoder, which will reset to its default state (F5 off) next time it turns on. | Comment: Some decoders save the state of their function outputs when shut down. Since this complicates using the decoder to turn off battery power, it's easier to initiate battery turn-off manually with a second on-board magnetic sensor. |