Introducing Steve Hayes

There are two reasons I invited Steve to describe his operational experience with S-CAB. He was an early user of the S-CAB system and wanted the system to solve real operational issues on his layout. His objective is prototypical operation of a model railroad and I figured a large layout with group operating sessions would be a serious test for S-CAB. For more info on Steve's Western Pacific layout, visit steveswplayout.hayeswp.com. Here is Steve in his own words.

History

Back in 1995, while designing my future Western Pacific layout, an important requirement was to escape the DC block system that had been used for many years. DCC was in its infancy at that time and while researching new systems I concluded DCC was still evolving and not yet ready for prime time.

The Western Pacific layout is designed for operation using a working Dispatchers Panel to control all turnouts and signals. Research lead me to the Chubb system that is basically a DC system with progressive block assignment. The selling point was the interface between dispatcher’s panel and signals. This system also did away with block switches.

The Chubb system has served me well over the years, although it has its drawbacks compared with today’s DCC. I have always said DCC is the Cadillac of operating systems, but for me, it's weak link is rail contact for both power pick up and transmitting instructions to decoders. I have a constant problem with dirty track; why, I have not figured out. We changed all the rolling stock to metal wheels, which helped some. A friend, John Zach (www.sierrarailroad55.com) went DCC a few years ago and it has been very successful.

John and I alternate operating sessions every Thursday with 10 to 14 operators for about 4 hours. We also have out of town operators come in 3 to 4 times a year and we try to keep the railroads compatible so that when groups visit no one is sitting unless they want to. This is where a problem began to manifest itself. John uses Easy DCC and has 8 mainline throttles, but the Chubb system only supports 7 mainline throttles. We can both have unlimited tethered throttles (my yards) but I am restricted to 7 mainline throttles.

For years I have searched for a solution, mainly looking at some sort of battery power to add an eighth throttle and maybe find a solution to dirty track. The G scale folks with plenty of space have the answer. Now HO guys need to follow suit. A friend and I experimented with inexpensive race cars and cobbled up a working throttle system. This worked for just running trains but was not acceptable for heavy operating that we do on Western Pacific. I was aware of different people working on battery power. I joined all the groups I could find and watched and listened, feeling a solution was not far off.

Then I met Neil Stanton at the 2011 NMRA Train show and felt he was on the right track (pardon the pun) with his S-CAB system. I asked if he needed a Beta tester but, being a electrical engineer, he figured he did not need one. He

got one anyway, as I purchased a unit and started corresponding with him regarding S-CAB performance on my layout. I guess that is why he asked me to document some of my operational experience. He told me to be candid, which is really the only way I would want to proceed anyway, although he did reserve editorial control.

got one anyway, as I purchased a unit and started corresponding with him regarding S-CAB performance on my layout. I guess that is why he asked me to document some of my operational experience. He told me to be candid, which is really the only way I would want to proceed anyway, although he did reserve editorial control.

First Installation

So here we go, the first unit arrived and I set about installing it in a HO Intermountain A/B unit. The B unit was a dummy (as was the person installing it, I’ve been told) so I felt there would be few problems and this was basically true. I was an early-adopter and the first generation battery boards were too wide to mount flat and needed to stand on their edge, as did the battery. I wanted the capability of recharging from track power as I did not want to handle the loco when charging the battery. The BPS on-board battery charging is one of the real selling points of the S-CAB system. Looking at the width of the board, it appeared that 2 traces (printed wire paths) served no purpose, so I asked Neil if I could remove them. He asked if I knew what I was doing and reminded me about what happens to warranty when you take a grinder to a product. I assured him I would take responsibility, as I had experience building all the Chubb system boards.

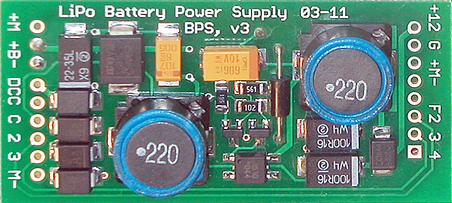

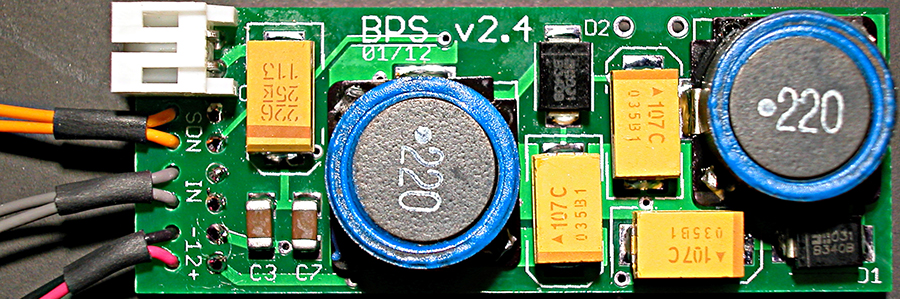

Anyway, Neil must have been convinced because the latest BPS board is 3/4" wide. The dates of the boards, March 2011 and January 2012 respectively (visible in the photos), shows the evolution.

Installation was simple and I soon had the unit on the track for the first operating session. I have 4 unit trains that go from one end of the railroad to the other as straight through runs and felt this would be the best place to use the S-CAB as beginners usually run these trains and this would remove any locomotive assignment requirements. The procedure is run out with one train, wait a while and return with another; then repeat the run. The run is about 900 feet in length each way. With a dispatcher setting signals and loco using battery power, everything worked as designed except for two block signals that need direction of travel. Since the BPS has track power pickup for battery charging, track occupancy detection works, and signals drop as a train enters each block (remember there is no track power on my railroad except when a cab is assigned to the block). All went well, the light on-off function was a bit temperamental so we just left the light on.

My initial concern was the throttle, which I thought was too wide to hold comfortably in one hand while uncoupling cars etc. On the Yahoo group there was a complaint that it had a slider instead of a knob, but that has been no problem. In fact, I have found the slider beneficial. I toyed with putting a lanyard on the throttle in case it was dropped but it has not been a problem. I had problems with reliability of the original "magic" wand turning on battery power. I found it easier to turn the unit on at the start of a session with a 9 volt battery touched across the track. The latest magic wand works like a charm!

During the first session, the train went out and back and out again, then died on the return trip! (That's nearing the end of 3,600 feet run with a 12 car freight train and no battery charging). Talking with Neil, we decided to send him the locomotive for some testing of battery life. In the meantime, I installed a short section of track at each end of the railroad as a service facility with power so the locomotive could charge between trips. Since Neil added a second battery in the unit, I can’t report if my charging stations or the extra battery solved the problem. However, there have been no further problems.

It's important to remember to turn the unit off at the end of each operating session or it will draw the battery down. Neil had installed an off switch that I just press with a small wire. One thing we did was have the running lights tied into the track pickup so I can see it's charging. At the end of a session I put the unit on a charging track overnight so it's ready for the next session as I have been told not to leave it with a low charge.

Second Installation

My next project was to try to get S-CAB into a yard switcher. The new parts Neil supplied were smaller than the first one I purchased but I tried every thing I could think of to get it to fit. Even removed the front drive gears, but to no avail. So I came up with the cow and calf configuration. I hooked a calf up to the switcher and let the crew try it for 3 sessions to see if having two units would be a problem. Then I installed all the components in the calf. I used both the cow and calf wheel sets for pickup and that is where I went wrong. I blew up the decoder. I sent the unit to doctor Neil and he found the loco motor was connected to rail pickup through the loco frame. With DCC, the motor cannot be grounded to the frame and mine was! I asked Neil, how was I supposed to know that, and he has now written some bureaucratic instructions to make users aware of this condition.

With the switcher we had to use a smaller battery so my plan from the offset was to leave track power on in the yard as mainline trains stay on the siding and do not enter the yard (intentionally). As usual, if there is a weak spot, operators find it. With battery power, there's no buzz when the turnout is against you; you just end up on the ground! Well, one night every time I went by the yard the operator was putting the locomotive back in the track and I think this drained the battery. We have never had a problem since. One thing that happened was the yard operator left the yard turnout lined for the yard and the incoming train entered the yard, hit the 8 volt yard power and launched! I added a dead section to eliminate that problem.

With BPS, the yard is a pleasure to operate; no stalls. To explain battery power I say, "remember when you brought that brand new locomotive home and put it on the track and it ran so smooth". Well, with battery power and no need for track power, it runs even smoother than originally!

I do not use the same throttle for multiple locos; each locomotive has its own throttle. I found while testing the switcher that the original unit took off because I forgot to enter the switcher's decoder address. I warned Neil that this would continue to be a problem and he provided a replacement chip with software changes so that each throttle switches on with a specific locomotive address already selected.

Third Installation

As with everything, the best made plans work for a while and then things change. It became apparent we could use another throttle as the Reno operator was using a tethered throttle to switch the yard and then switched over to a mainline throttle to go out on the main to Oakland. This required a panel switch to change from tethered to mainline throttle and we all know that the less “model railroad” we have the better.

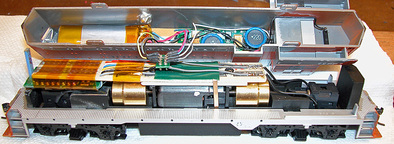

So I sent a Kato GP35 to Neil to see if he could get the components into just the locomotive! Check it out on the website as he documented the work. One

might ask why I have Neil help with the installations. Well, it's twofold. One he does beautiful work and the other; I keep nagging him to get information out there with photos of what can be done. A picture is worth a 1000 words especially to those of us that are a bit skeptical of something new.

might ask why I have Neil help with the installations. Well, it's twofold. One he does beautiful work and the other; I keep nagging him to get information out there with photos of what can be done. A picture is worth a 1000 words especially to those of us that are a bit skeptical of something new.

We ran the GP35 for the first time during a recent session. It switched the yard for about 30 minutes, then ran to Oakland doing some switching along the way. It then returned to Reno and finished up the switching there, all in all, about 2 ½ hours of running. I did not have the yard power on to recharge the battery while working the yard, but I plan to do this as a backup. The only thing we notice was there was occasional low speed creep. I'm sure there is a reason for this. Neil is usually pretty good about tracking and fixing these types of problems. We are currently running 3 throttles. Two are used for switching the yards and one on the mainline. We have not noticed interference between them, although Neil tells me that low speed creep may be an indication of radio interference.

Conclusion

To sum it up, I could not be happier with the S-Cab system. As further development occurs, I expect components will become smaller and installation should be easier. Anyone starting out should give S-CAB a serious look. To build a railroad without wiring and not having to clean track has to be a big plus for newbie’s to the hobby. I strongly believe that this will become a future standard. Since it does not require those on DCC to upgrade, there is no worry about DCC through-the-rails becoming obsolete. As I said earlier DCC is the Cadillac of operating systems; now I can say, battery power with S-CAB is the Rolls-Royce!