Radio Control, No batteriesLayout is wired for DC operation.

Objective: Add DCC capability in some locos without changing any layout wiring. For example, add a sound decoder to a DC powered loco.

Solution: This is the simplest application of radio control and begins with only two pieces of equipment: An S-CAB Throttle and a radio-ready DCC decoder. As time and budget permits, more locos can be equipped with radio-ready decoders. If desired, add another Throttle for a second operator.

Next step: Make email contact to order an S-CAB Starter Kit, which includes an S-CAB Throttle and a compatible radio-ready sound, or non-sound decoder.

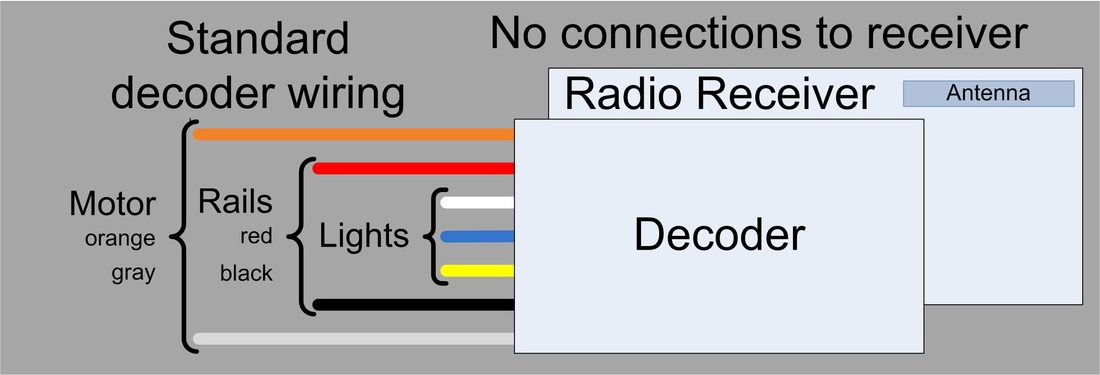

Installation: Connections for a radio-equipped decoder are identical to those of the same decoder without radio receiver. However, location of the radio antenna can affect radio reception, especially in metal locos.

Pro: A simple way to equip a loco with DCC functionality without the cost or frustration of making layout wiring compatible with DCC.

Con: Constant track voltage (approx 12 volts) is required for loco power. Speed control is performed by the decoder; not by variable voltage on the track.

|

Batteries, No Radio ControlLayout fully operational with DCC.

Objective: Eliminate unreliable rail contact, but retain thru-the-track DCC. If stay-alive capacitors don't drive locos across track where dirt accumulates or through switches with occasional power loss, backup battery power will do the job reliably.

Solution: This requires an S-CAB BPS and battery to provide backup power. Locos are controlled by existing DCC equipment. Track power, when available, powers loco and charges the battery. When track power fails, battery power keeps decoder and loco operating for several minutes to half an hour, depending on size of the battery.

Next step: Before placing an order, send an email to discuss requirements. This includes choice of battery and location of equipment within the loco.

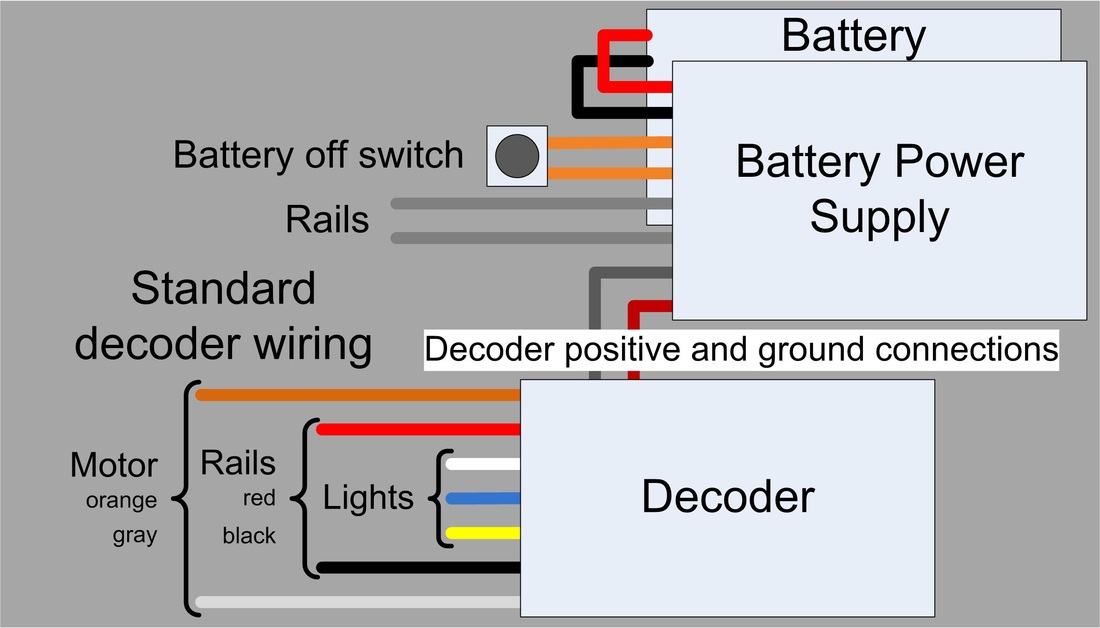

Installation: Rail pickup is connected to both decoder and BPS. BPS 12 volt output is connected to decoder positive common (the blue wire) and ground (unfortunately, not externally available on some decoders). However, the same connections are used for keep-alive capacitor installations. If agreed, a decoder can be mailed to me for correct connections.

Pro: A superior method to eliminate momentary power interruptions of track power pickup. Even a small battery will keep a loco running for 10 minutes or longer.

Con: Not a popular option, since combining battery power with radio control provides same benefits with superior operational convenience and similar installation effort.

|

Radio Control and BatteriesLayout not wired or partly wired.

Objective: Avoid or simplify layout wiring.

Solution: Both an S-CAB radio-ready decoder and BPS are required in each loco. An S-CAB Throttle is required for each operator. To avoid purchase of unnecessary equipment, choice of radio control and battery power should be made early in layout planning. DCC equipment and layout wiring costs that are avoided will offset higher cost per loco for radio and battery power.

Next step: Make email contact to discuss layout wiring and operating requirements.

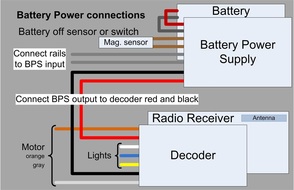

Installation: Rail pickup (or alternative power input) is connected to the BPS. The decoder's right/left rail connections (red/black wires) are connected to BPS output. The system will be delivered with two pre-wired and tested modules; the BPS with battery as power supply; the radio receiver and decoder as control system.

Pro: The most popular option.

Con: Possibility of radio interference from conventional DCC wireless throttles.

|